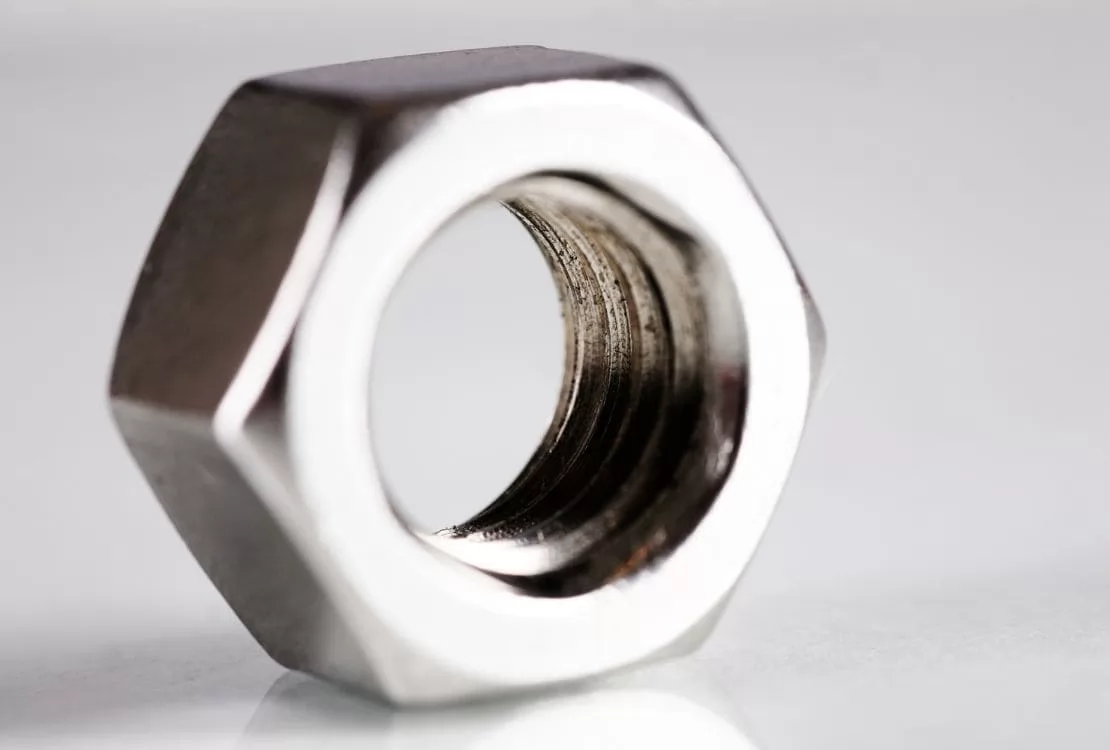

Hex nuts are an essential part of fastener systems, widely used in various industries, from construction and automotive to furniture and machinery. Their primary function is to securely fasten components together, preventing loosening due to vibrations or movements. The quality of hex nuts directly affects the integrity and safety of the assemblies they are used in. For this reason, selecting a reliable hex nut manufacturer is crucial.

This guide is designed to help you understand the factors to consider when choosing a manufacturer for hex nuts. We will delve into the characteristics that define high-quality hex nuts, why material selection is important, and how precision in manufacturing ensures reliable performance. Additionally, we will highlight the strengths of Yuyao Meigesi Fastener Co., Ltd., a renowned manufacturer specializing in the production of high-quality hex nuts and other fasteners. Whether you are looking for standard or custom solutions, this guide will provide the insights you need to make an informed decision.

Hex nuts are designed to provide a secure, tight fit when paired with a bolt or screw. A high-quality hex nut ensures that the fastening system remains reliable under stress, vibration, and exposure to harsh environmental conditions. Let’s take a closer look at the key attributes that distinguish premium hex nuts.

The durability of a hex nut is one of the most important factors in ensuring the longevity of any assembly. A high-quality hex nut is made from strong materials like stainless steel, alloy steel, or brass, which offer excellent resistance to corrosion, wear, and high pressures. The strength of a hex nut, usually specified in grades such as 4.8, 5.8, 8.8, or even 12.9, determines how well it can withstand stress before deforming or failing.

Hex nuts must feature precisely cut threads that align perfectly with bolts or screws. This accuracy is essential for a strong and reliable connection, preventing the nut from slipping or becoming loose over time. Quality control during manufacturing ensures that the threads are uniform and meet international standards such as DIN, ISO, ANSI, and JIS.

The choice of material directly impacts the performance of hex nuts. Different materials are suited for different applications. For example, stainless steel hex nuts are perfect for environments that require high corrosion resistance, such as in marine or chemical industries. Alloy steel hex nuts are ideal for high-strength applications like heavy machinery, while brass nuts may be chosen for aesthetic or non-corrosive uses in the electronics or furniture industries.

Yuyao Meigesi Fastener Co., Ltd. has established itself as a leading manufacturer of high-quality hex nuts and other fasteners. With decades of experience and a focus on innovation and quality, Meigesi has earned the trust of clients worldwide. Here’s why Meigesi stands out as the go-to manufacturer for hex nuts:

Meigesi offers a wide variety of hex nuts, including standard and customized solutions. From American Hexagon Nut Grade 5 to Heavy Hex Structural Nut A563-DH, they meet the needs of different industries and applications. Their range also includes thin nuts (DIN439/DIN936) and specialty nuts designed to handle specific conditions such as heavy loads or corrosive environments.

Meigesi understands that each project may have unique requirements. Whether you need custom sizes, coatings, or materials, Meigesi offers tailored solutions to meet your exact specifications. This flexibility ensures that clients receive products that align perfectly with their assembly needs.

With an extensive customer base spanning countries such as Russia, Poland, Ukraine, Australia, Germany, and the USA, Meigesi has built a strong reputation as a reliable supplier of fasteners. Their ability to meet international standards and provide consistent, high-quality products has made them a trusted partner for many industries.

Meigesi prioritizes quality control at every stage of production. Using advanced manufacturing technologies and adhering to strict quality standards, they ensure that each hex nut meets the highest industry benchmarks. Additionally, they offer a range of grades, including 4.8, 5.8, and 8.8, providing customers with options that match their specific needs for strength and durability.

Meigesi specializes in a wide variety of hex nuts designed to serve various industrial applications. Below are some of the most popular types of hex nuts available from Meigesi:

These nuts, such as the Heavy Hex Nut A194-2H, are designed for use in high-stress environments where maximum strength is required. They are commonly used in structural applications and heavy machinery.

Meigesi also manufactures Heavy Hex Structural Nuts A563-DH, which are used in construction, mechanical, and other structural projects. These nuts are built to withstand extreme loads and provide lasting performance.

For applications where space is limited, Meigesi offers Thin Hex Nuts (DIN439/DIN936). These are ideal for uses where a low profile is needed but still require strong and secure fastening.

Grade 5 American hex nuts are widely used in automotive and machinery applications. Meigesi’s American Hexagon Nut Grade 5 provides the perfect balance of strength and versatility for general applications.

If you are looking to source high-quality hex nuts, partnering with Meigesi is a straightforward and efficient process. Here are the steps to get started:

Start by discussing your project requirements with Meigesi’s sales team. They will review your needs in terms of size, material, and application, helping you choose the right hex nuts for your specific requirements.

Once the specifications are finalized, Meigesi will begin the production process. If customization is required, such as special coatings or sizes, the company will work with you to ensure the final product meets your expectations.

Meigesi’s established international shipping network ensures that your order arrives on time, regardless of your location. The company offers flexible delivery options to meet urgent project timelines.

At Meigesi, quality is at the heart of everything they do. The company’s dedication to producing high-quality fasteners is reflected in its rigorous quality control processes and commitment to meeting international standards. Meigesi’s focus on customer satisfaction ensures that every order, large or small, is handled with the utmost care.

The manufacturing process for hex nuts is a complex and highly precise operation. From the selection of raw materials to the final inspection, each step is critical in ensuring the nut meets industry standards.

Hex nuts are used in a wide range of industries, including construction, automotive, and electronics. Understanding the applications of hex nuts in different sectors can help you choose the right manufacturer for your specific needs.

Certifications are a key indicator of a manufacturer’s commitment to quality. Meigesi holds certifications that guarantee their products meet international standards, ensuring that their hex nuts are suitable for various industrial applications.

Hex nuts are in high demand globally, driven by their use in infrastructure projects, machinery, and consumer goods. Meigesi has seen a steady rise in exports, with their products being shipped to markets around the world.

A: High-quality hex nuts are durable, precise, and made from reliable materials that meet industry standards.

A: Meigesi is known for its commitment to quality, extensive product range, and global reputation.

A: Yes, Meigesi offers customization options for sizes, materials, and coatings.

A: Meigesi serves industries such as construction, automotive, furniture, and heavy machinery.

A: Meigesi employs advanced production processes and strict quality control measures to ensure consistent quality.

A: Contact Meigesi, discuss specifications, finalize orders, and arrange delivery.