In the production of nuts, various issues can arise, including cracking and deformation, surface defects, dimensional nonconformity, and uneven hardness. Cracking is a significant issue as it can lead to loosening or separation of connected components, potentially causing mechanical failures. If not promptly addressed, these failures can result in production stoppages, reduced efficiency, and increased maintenance costs. Therefore, understanding how to handle nut cracking is crucial, especially for any reliable nuts manufacturer.

There are multiple reasons why nuts might crack during production, and identifying these causes is key to resolving the issue effectively.

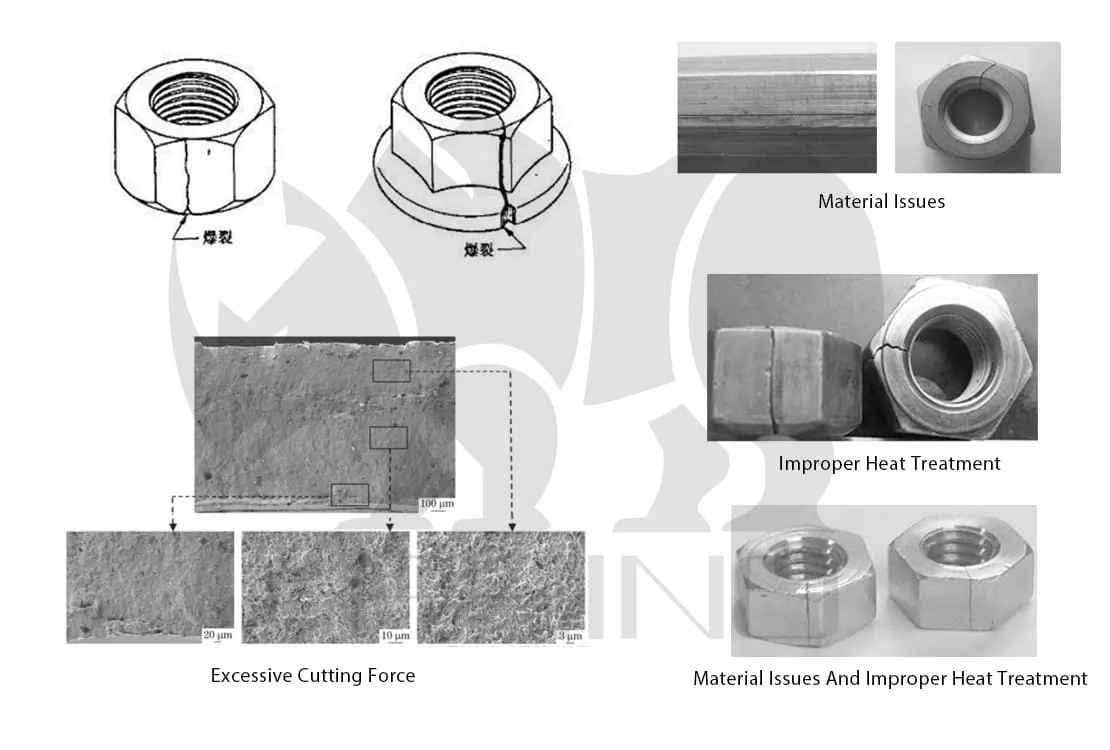

One of the most common reasons for nut cracking is substandard material quality. If the raw material contains impurities or internal defects, the nuts are prone to cracking during processing. Even if cracks don't occur immediately, the overall quality and usability of the nuts will be compromised. For any nuts manufacturer, ensuring stable material quality is essential to avoid significant losses. That’s why we at Meigesi have established long-term partnerships with reputable raw material suppliers. We also conduct random inspections and maintain a traceability system to monitor the quality of each batch of materials.

Another frequent cause of nut cracking is improper heat treatment. Overheating during the production process can easily lead to cracks. To prevent this, we regularly train our technical personnel to strictly control temperature and cooling rates during heat treatment. In case of overheating, production is stopped immediately, and the product's condition is closely monitored. We then analyze whether tempering is necessary to remedy the situation.

While relatively rare, excessive cutting force can also lead to nut cracking. At Meigesi, we have developed a mature production system that sets cutting parameters precisely, minimizing the likelihood of this issue. However, if it does occur, our technical team promptly adjusts the cutting force and speed to reduce stress on the nuts and prevent further cracking. In the past, when dealing with new materials, we encountered this issue, but quick adjustments resolved the problem, ensuring the quality of our products.

Stress corrosion is another rare occurrence but can affect nuts if not managed correctly. In such cases, surface treatments like galvanizing or coating are applied to enhance the nuts' corrosion resistance. As a trusted nuts manufacturer, we work with specialized factories to apply these treatments to meet our customers' requirements.

To ensure smooth production, it is essential for those responsible to inspect semi-finished products regularly. This helps identify thread cracking early, allowing for timely corrective actions. Furthermore, employee training, mentorship programs, and experience-sharing sessions are crucial for empowering our staff to handle issues promptly.

Established in 2010, Yuyao Meigesi Fastener specializes in the production and export of various fasteners, including screws, nuts, and bolts. As a professional nuts manufacturer, Meigesi exports products to over 50 countries across Eastern and Western Europe, and South America. With 13 years of experience, we have built a reputation based on professionalism, efficiency, and innovation, continuing to grow in the global fastener industry.