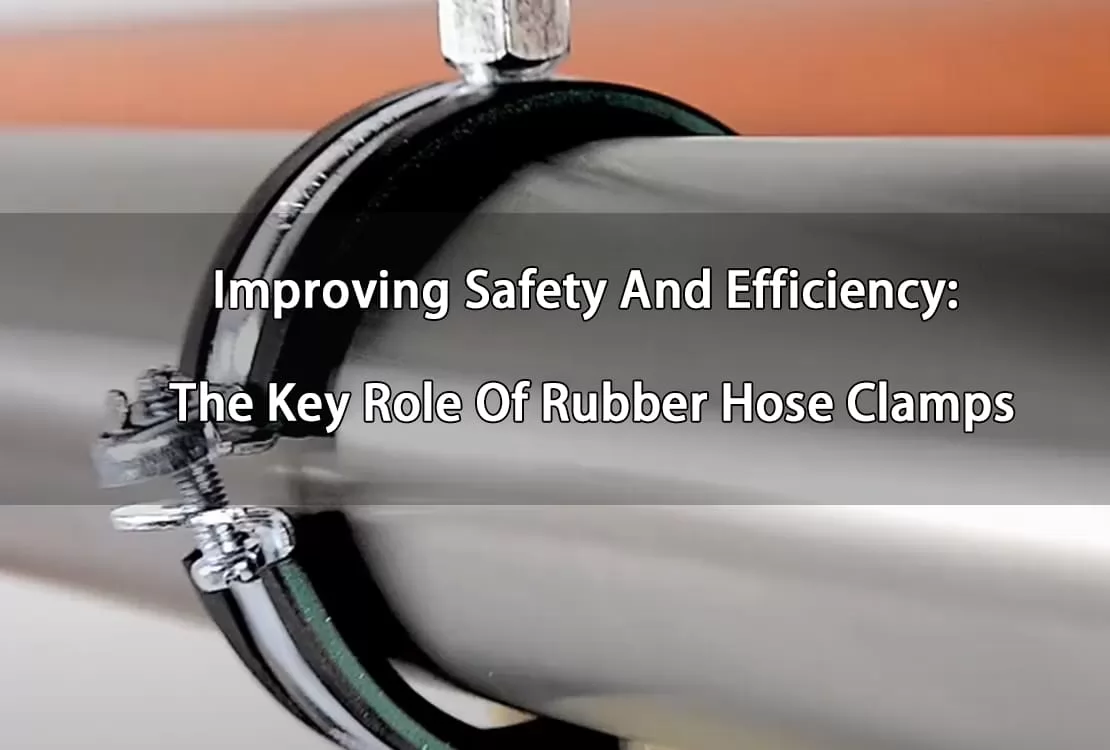

A rubber hose clamp is a device used for securing and supporting pipes. It typically consists of a metal clamp and a rubber insert. These clamps can effectively reduce pipe vibrations and noise while providing stable support to prevent pipe displacement. They can be used for connecting and securing water pipes, oil pipes, gas pipes, and other rubber hoses. Due to their convenience and stability, they are widely used in industries, automotive applications, and household equipment.

Common materials for these products include stainless steel, galvanized steel, and nylon. They are characterized by their corrosion resistance, high-temperature resistance, and wear resistance.

The importance of rubber hose clamps lies in their critical role within piping systems.

Rubber hose clamps securely fasten rubber hoses to connectors, preventing the leakage of liquids or gases. In hydraulic systems, fuel systems, or water supply systems, leaks can lead to energy waste, environmental pollution, and even safety incidents.

Under conditions of vibration, pressure changes, or temperature fluctuations, rubber hose clamps can prevent pipes from loosening or detaching, ensuring a tight connection.

These clamps are typically made from corrosion - resistant and high - temperature - resistant materials, such as stainless steel and nylon, to withstand harsh working environments. This durability is especially important in industrial equipment or outdoor applications.

By ensuring a tight pipe connection, rubber hose clamps help maintain system pressure stability, thereby enhancing system operational efficiency.

In systems involving high pressure, high temperatures, or hazardous media such as fuel or chemicals, rubber hose clamps can prevent accidental leaks or detachment, safeguarding personnel and equipment.

Despite their low cost, rubber hose clamps can avoid repair expenses and production losses caused by pipe loosening or leakage. Their use can extend the lifespan of pipes and equipment, reducing maintenance costs.

Rubber hose clamps come in various materials. Selecting the appropriate material based on different application scenarios and requirements ensures the durability, corrosion resistance, and adaptability of the clamps. Rubber hose clamps consist of a metal clamp and a rubber insert. Common materials for the metal part include: stainless steel, galvanized steel, nylon, carbon steel, aluminum alloy, and polypropylene (PP).

1. Stainless steel features: Strong corrosion resistance, suitable for humid, high temperature or chemical corrosion environment. High strength, good durability, suitable for high pressure or high vibration scenes. Commonly used in automotive fuel systems, industrial hydraulic systems, marine equipment, etc.

2. Features of galvanized steel: The surface is galvanized and has a certain anti-rust ability. It has a low cost and is suitable for use in general environments. It is commonly used in household appliances, general industrial equipment, etc.

3. Nylon (plastic) Features: light weight, corrosion resistance, good insulation. Suitable for low pressure and low temperature environment, low cost. Commonly used in household equipment (such as washing machines, dishwashers), low pressure pneumatic systems, etc.

4. Carbon steel features: high strength, low cost, but easy to rust. Usually requires surface treatment (such as spraying or plating) to improve corrosion resistance. Commonly used in general industrial equipment and non-corrosive environments.

5. Aluminum alloy features: light weight, good corrosion resistance, moderate strength. Suitable for scenes that need to reduce weight, usually used in automobiles, aviation equipment, and light industrial equipment.

6. Copper features: good corrosion resistance, high thermal conductivity, but high cost. Suitable for special environments (such as high temperature or highly corrosive media). Relatively rare, used in high-end products.

7. Polypropylene (PP) or other engineering plastics features: chemical corrosion resistance, good insulation, light weight. Suitable for low pressure and low temperature environment.

When selecting materials, we should consider factors such as temperature, humidity, corrosive media, cost, weight, whether insulation is required, etc. For example, stainless steel is usually selected in a humid and corrosive environment.

Pipe Clamp With Rubber https://www.meigesi.com/pipe-clamp-with-rubber/

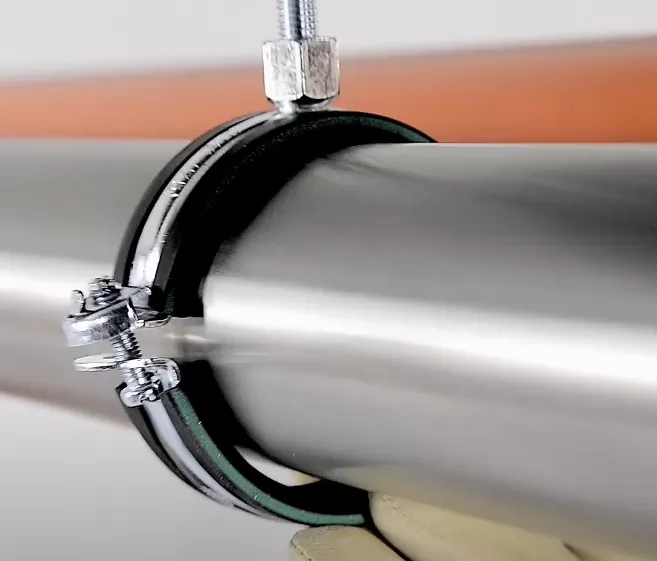

Installation of rubber hose clamp

1. Preparation before installation

Check the pipe clamp and pipe: make sure the size of the pipe clamp matches the outer diameter of the pipe, and the pipe surface is not damaged or deformed.

Clean the connection parts: remove dust, oil or rust on the pipe and joints, and ensure that the contact surface is clean.

Prepare tools: prepare appropriate tools according to the type of pipe clamp, such as screwdrivers, wrenches or special installation tools.

2. Installation steps

Step 1: Place the pipe clamp, put the rubber pipe clamp on the pipe connection, and make sure the pipe clamp is in the correct position (usually close to the joint).

Step 2: Adjust the tightness. For worm-type pipe clamps, tighten the screws with a screwdriver or wrench until the pipe clamp tightly fixes the pipe. For spring-type pipe clamps, directly clip it into the pipe connection and ensure that the spring tension is uniform.

Step 3: Check the fixing effect. Gently pull the pipe to check whether the pipe clamp is firm and ensure that the pipe will not loosen or fall off.

Step 4: Test the sealing. Before the system is operated, perform a pressure test or water/air test to ensure that there is no leakage.

3. Installation precautions

Do not over-tighten the screws to avoid damaging the pipe or pipe clamp.

Ensure that the pipe clamp is in even contact with the pipe to avoid excessive local force.

In high temperature or high pressure environments, choose pipe clamp materials that are resistant to high temperature and high pressure.

At the end of the article, I would like to discuss the application of rubber hose clamps in earthquake-resistant and anti-vibration systems. Rubber hose clamps are mainly used in earthquake-resistant and anti-vibration systems to provide reliable fixation and protection for various pipelines, pipes and devices. Through its unique structural design, rubber hose clamps can maintain stability in complex environments and ensure the safe operation of pipelines and pipes. When natural disasters such as earthquakes occur, rubber hose clamps can effectively absorb and disperse impact forces, reducing displacement and damage to pipelines caused by vibration.