Fasteners serve as fundamental components across industries like machinery manufacturing, building structures, and transportation. Their performance reliability directly influences the safety and stability of entire systems. Among the many performance factors, corrosion resistance stands out as a critical metric. To assess this, salt spray testing has emerged as a widely recognized, scientific method for evaluating fastener quality and durability.

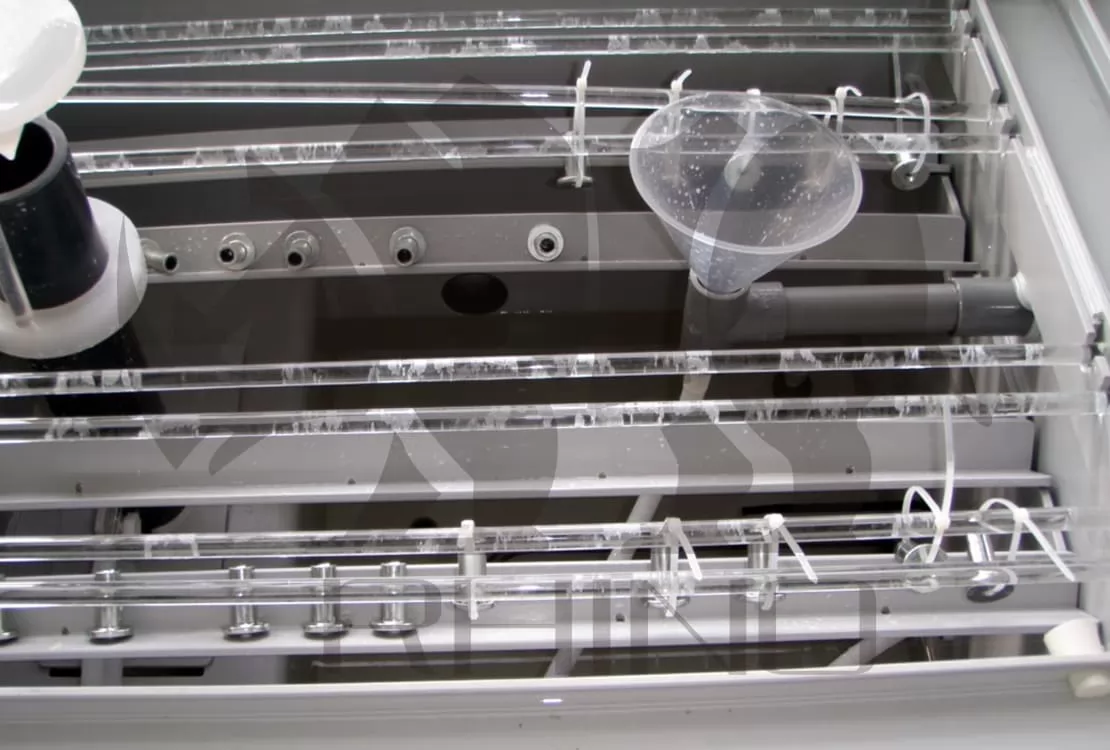

A salt spray test is an experimental technique designed to accelerate the corrosion of metal materials by replicating the salty, corrosive conditions found in marine climates. Conducted within a specialized salt spray test chamber, this method involves generating a mist from a sodium chloride (salt) solution of a specific concentration. Fasteners are then exposed to this controlled environment, allowing researchers to observe and analyze surface corrosion over time. The results offer valuable insights into fastener quality, the effectiveness of manufacturing processes, and their long-term durability in real-world settings.

Salt spray tests vary based on their purpose and conditions, each tailored to specific evaluation needs. Here are the primary types:

Neutral Salt Spray Test (NSS)

The most widely adopted standard method, NSS uses a 5% sodium chloride solution as its corrosive medium. With relatively mild test conditions, it provides a baseline for assessing corrosion resistance across a range of fasteners.

Acetic Acid Salt Spray Test (AASS)

This test enhances the NSS method by adding glacial acetic acid to the sodium chloride solution, creating a mildly acidic environment. AASS is particularly effective for evaluating the corrosion resistance of plated products, offering a more aggressive testing scenario.

Copper Accelerated Acetic Acid Salt Spray Test (CASS)

Building on AASS, the CASS method introduces copper ions to further accelerate corrosion rates. This rigorous test is ideal for assessing materials engineered for high corrosion resistance, providing fast, reliable data for advanced applications.

By simulating harsh environmental conditions, salt spray testing delivers a scientific foundation for understanding how fasteners will perform over time. Whether ensuring the longevity of machinery, the integrity of building structures, or the safety of transportation systems, this method helps manufacturers optimize quality and meet industry standards. For businesses and engineers alike, choosing the right test—be it NSS, AASS, or CASS—ensures that fasteners can withstand the challenges of their intended environments.