Historically, domestic electromechanical facilities focused on load-bearing capacity often overlooked earthquake-resistant design, posing significant safety risks. The Code for Seismic Design of Mechanical and Electrical Systems in Buildings formalized seismic support systems as essential safeguards. By integrating load mechanics and seismic action calculations, these systems anchor pipelines, ducts, cable trays, and equipment to pre-reinforced building structures. This method minimizes displacement, controls vibrations, and transfers seismic forces to load-bearing components, prioritizing life safety and reducing earthquake-induced damage. Known as Seismic Support and Hanger systems, they are now a cornerstone of industrial and large-scale construction projects.

These systems balance flexibility and rigidity through advanced engineering:

1. Vibration Absorption

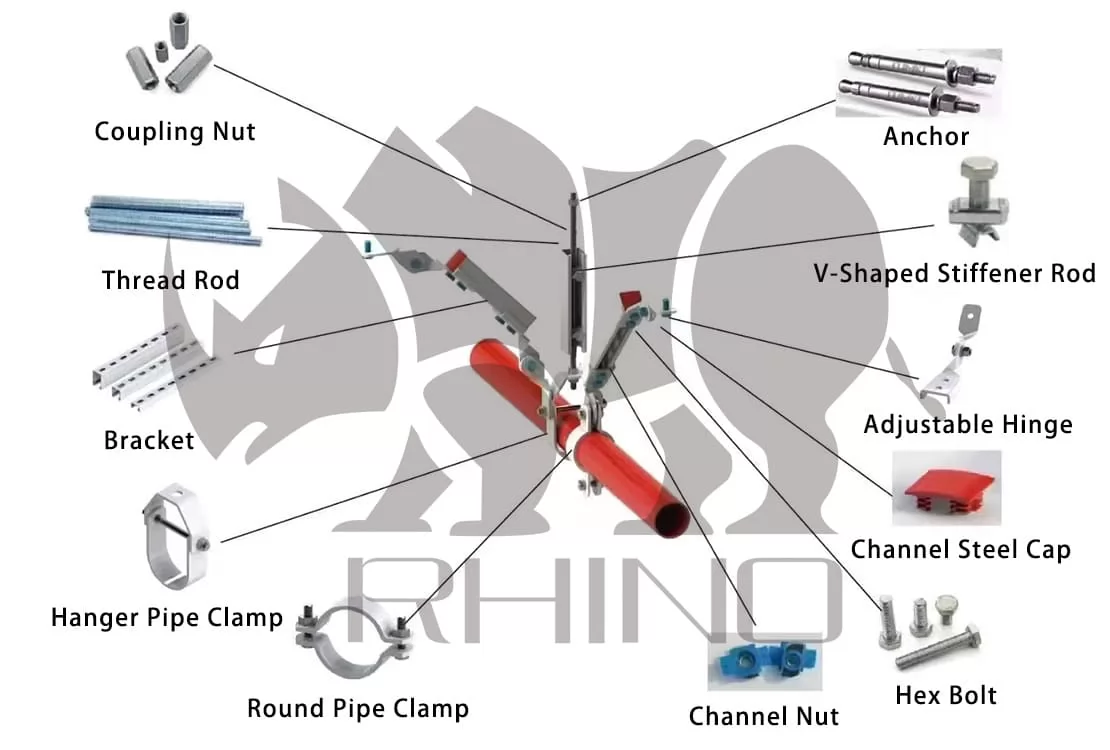

Elastic Components: Parts like the Channel Nut With Plastic Holder absorb seismic energy, isolating pipelines from direct shockwaves.

Energy Dissipation: Flexible materials reduce resonance effects, preventing structural fatigue.

2. Structural Reinforcement

High-Strength Fasteners: Components such as V-Shaped Stiffener Rods, Hexagonal Coupling Nuts, and Thread Rods enhance rigidity, resisting deformation during seismic events.

Anti-Slip Design: Textured surfaces and locking mechanisms prevent equipment slippage.

3. Multi-Directional Constraints

Adjustable Brackets: Provide horizontal, vertical, and diagonal support to stabilize equipment under complex forces.

Load Distribution: Redirect seismic energy across multiple anchor points, avoiding localized stress failures.

Mandated by China’s Building Law and Earthquake Disaster Prevention Law, seismic systems protect vital infrastructure:

1. High-Rise Buildings

Secure HVAC ducts, electrical conduits, and fire suppression pipelines, ensuring functionality post-earthquake.

Example: Hospitals and data centers rely on these systems to maintain critical operations during disasters.

2. Industrial Complexes

Petrochemical plants, power stations, and nuclear facilities use seismic supports to prevent leaks, explosions, and production halts.

Case Study: A refinery in seismic Zone 7 reduced downtime by 40% after retrofitting with seismic hangers.

3. Transportation Networks

Reinforce bridges, tunnels, and rail systems to withstand ground motion, ensuring evacuation routes remain intact.

4. Public Spaces

Theaters, stadiums, and airports integrate seismic systems to protect overhead installations like lighting and signage.

1. Material Durability

Opt for galvanized carbon steel or stainless steel to combat corrosion and extend service life.

Avoid low-cost alloys that may degrade in humid or chemical environments.

2. Compliance Standards

Ensure products meet GB/T 37267-2018 (China’s seismic code) and international certifications like ISO 16134.

3. Customization Needs

Choose suppliers offering tailored solutions for irregular layouts or heavy-duty equipment.

Advancements in smart monitoring and self-adjusting systems are transforming seismic solutions:

· Sensor-Embedded Hangers: Detect stress levels and send real-time alerts for maintenance.

· Shape-Memory Alloys: Automatically regain original form after deformation, improving resilience.

· Modular Designs: Simplify retrofitting in older buildings without major structural changes.

As a trusted provider of seismic fasteners, Meigesi Fastener delivers:

· Premium Materials: Corrosion-resistant galvanized steel and stainless steel components.

· Precision Engineering: Thread rods, anchors, and brackets designed for seamless integration.

· Comprehensive Range:

Seismic Support and Hanger systems are no longer optional—they are non-negotiable safeguards for modern infrastructure. By combining rigorous engineering, compliant materials, and adaptive designs, these systems mitigate risks and ensure operational continuity during earthquakes. For reliable, code-compliant components, explore Meigesi Fastener’s seismic product line, engineered to protect lives and assets in the most demanding environments.