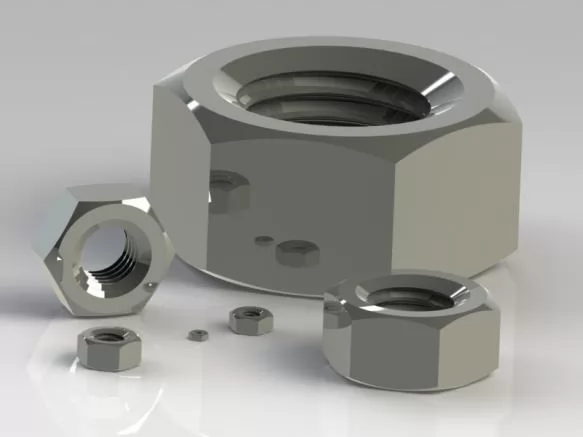

Hexagon nuts may seem like small, ordinary objects, but they play a critical role in countless industries and everyday applications. From towering construction projects to the furniture in your home, hex nuts are essential for ensuring stability and durability. In this article, we’ll explore the history, types, and applications of hex nuts, and explain why Meigesi Fastener stands out as a trusted hex nuts manufacturer.

Hex nuts are fasteners used in conjunction with bolts, screws, and other threaded components to securely join mechanical parts. They come in various types, each designed for specific applications:

Type 1 Hex Nuts: The most commonly used, with a nominal height of m≥0.8D. These nuts comply with GB/T6170 standards and are ideal for general-purpose fastening.

Type 2 Hex Nuts: Thicker than Type 1, these nuts are used in applications requiring frequent assembly and disassembly. They comply with GB/T6175 standards.

Hex Thin Nuts: Designed for situations where space is limited, these nuts are thinner and perfect for compact assemblies.

Hex nuts are also classified by thread pitch (standard, fine, very fine, and reverse threads), material (stainless steel, carbon steel, copper, and iron), and usage method (hot-melt, hot-press, embedded, and ultrasonic).

The history of hex nuts dates back to the Industrial Revolution in the 19th century. As machinery manufacturing advanced, the need for reliable fastening solutions grew. The hexagonal design became the standard due to its ease of tightening and excellent grip. By the mid-20th century, the introduction of materials like stainless steel and alloy steel further enhanced the strength and corrosion resistance of hex nuts, solidifying their place in modern industry.

Hex nuts are named for their six-sided shape, which allows for easy tightening with tools. The internal threads match the threads of bolts, ensuring a secure fit. Key features include:

Flat Faces: Distribute pressure evenly when tightened, preventing deformation.

Chamfer Design: Helps the nut start threading onto the bolt more easily, reducing thread damage.

Hex nuts are typically made from carbon steel, stainless steel, brass, alloy steel, or plastic. Carbon steel is the most common due to its strength and durability. For enhanced corrosion resistance, surface treatments like galvanizing, nickel plating, and phosphating are applied.

Hex nuts are indispensable in a wide range of industries:

Construction and Engineering: Used to secure structures and mechanical parts, ensuring stability and safety.

Automotive Manufacturing: Essential for fixing engine components, frames, and accessories, guaranteeing vehicle reliability.

Household Appliances: Found in refrigerators, washing machines, and other appliances, providing durable fastening solutions.

Furniture Assembly: Commonly used in DIY furniture to connect wooden and metal parts.

To ensure optimal performance, follow these guidelines:

Choose the Right Size: The nut must match the bolt size for a secure fit.

Use Proper Tools: Hex wrenches and torque wrenches are ideal for tightening and loosening.

Apply Correct Tightening Force: Over-tightening can damage threads, while under-tightening may cause loosening.

The future of hex nuts is marked by technological advancements and material innovations. For example:

Anti-Loosening Nuts: Provide reliable fastening in high-vibration environments.

Self-Locking Nuts: Eliminate the need for additional locking mechanisms.

New Materials: Alloys and composites are being used to enhance strength, durability, and corrosion resistance.

At Meigesi Fastener, we pride ourselves on being a leading hex nuts manufacturer. Here’s why you should choose us:

Premium Materials: Our hex nuts are made from high-quality carbon steel, stainless steel, and brass, ensuring exceptional strength and durability.

Wide Range of Specifications: We offer hex nuts in various sizes and types to meet diverse application needs.

Advanced Surface Treatments: Options like galvanizing, nickel plating, and phosphating enhance corrosion resistance.

State-of-the-Art Manufacturing: Our professional production equipment and technology guarantee precision and reliability.

Proven Track Record: Our hex nuts are trusted in industries like construction, automotive, and appliances, demonstrating their unmatched performance.