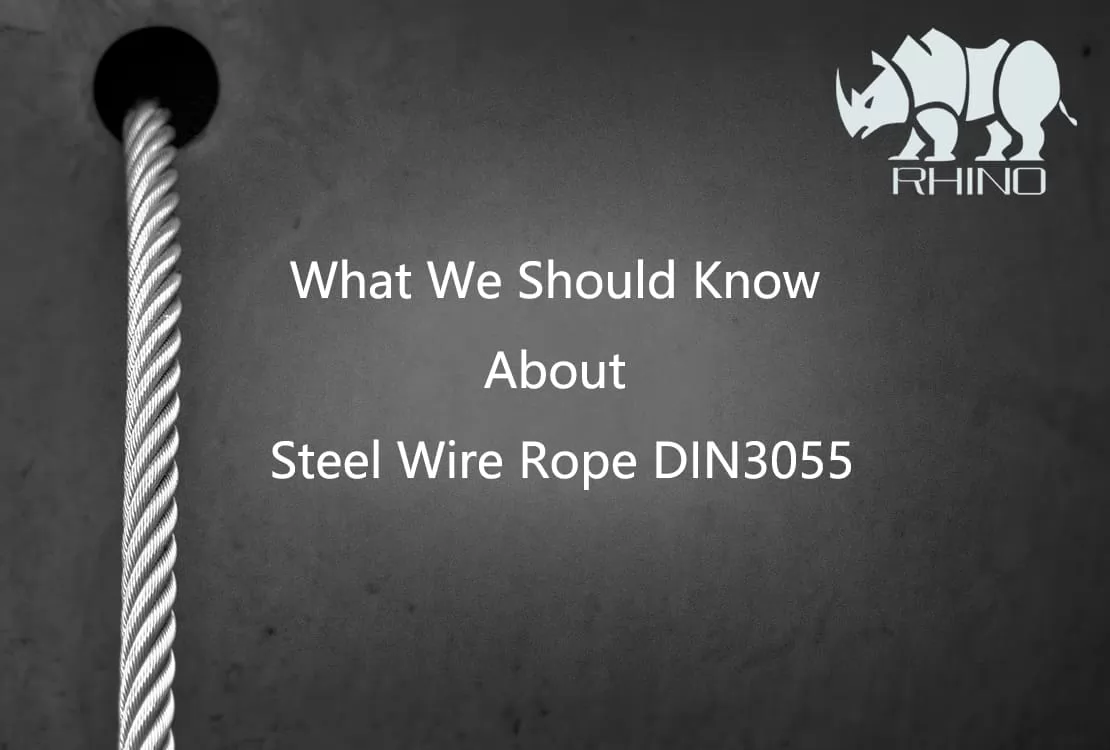

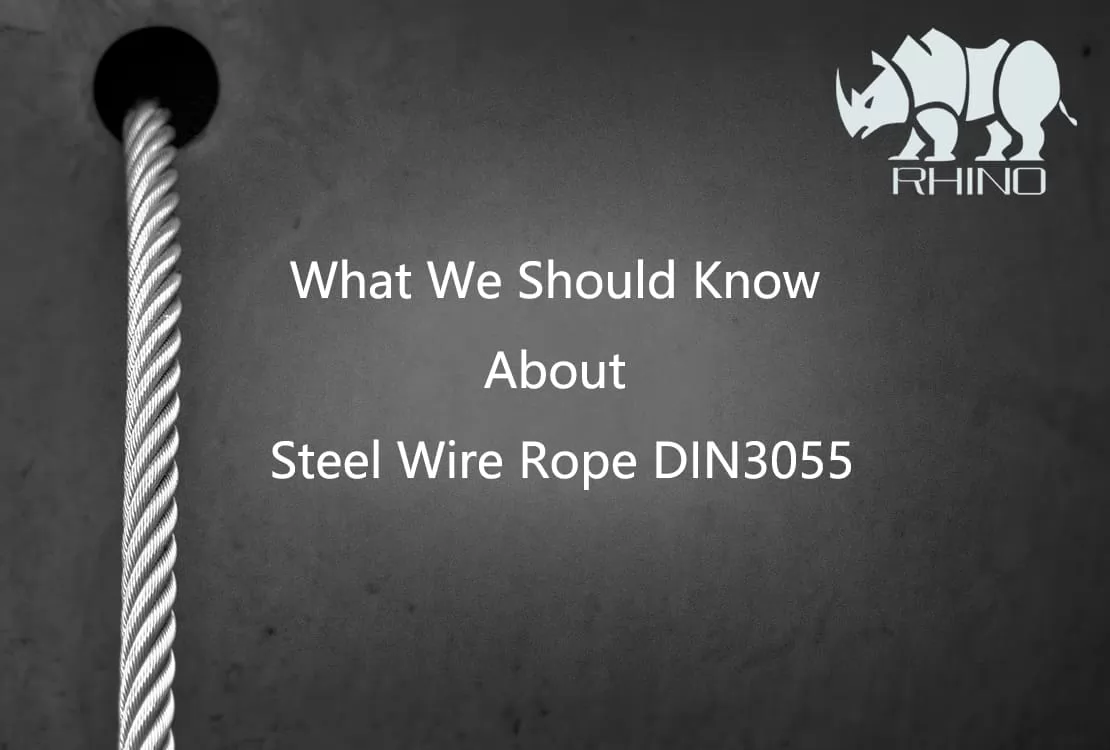

What is Wire Rope?

Steel wire rope is a spiral bundle of steel wires with specified mechanical properties and geometrical dimensions twisted together according to certain rules. The steel wire rope consists of steel wires, a rope core, and lubricant. It is first twisted into strands from multiple layers of steel wires, and then the strands are twisted into a spiral rope around a central core. In material handling machinery, it is used for lifting, traction, tensioning, and bearing. Steel wire rope has high strength, light weight, smooth operation, and is not easily broken suddenly, making it reliable for work.

Steel Wire Rope DIN3055 is a steel wire rope that meets the DIN 3055 standard established by the German Institute for Standardization (DIN). This type of steel wire rope typically consists of 6 strands, with each strand comprising 7 wires (6x7 structure), and the strands are arranged around a central rope core.

Standard Specifications:

-

Materials: Steel wire rope can be made of uncovered steel, galvanized steel, or stainless steel (A2, A4).

-

Diameter: The diameter of the steel wire rope ranges from 1 millimeter to 16 millimeters.

-

Length: The length of the steel wire rope can range from 1 meter to 2000 meters.

-

Structure: The typical structure is 6x7, but other structures such as 7x7 are also available.

Application Areas:

Due to the unique properties of wire rope, a more ideal product has not been found at home and abroad to replace wire rope comprehensively or in one field. Therefore, wire rope has become an indispensable component or material in the fields of metallurgy, mining, oil and gas drilling, machinery, chemical industry, aerospace, etc. Its quality has also been paid attention to by many domestic industries, and a lot of manpower and material resources have been invested in research on the use of wire rope and product development.

Quality judgment:

-

Specific Gravity: For steel wire ropes of the same diameter, the heavier the specific gravity, the better the quality of the steel wire rope.

-

Steel Wire Rope Core: The firmer and heavier the core of the steel wire rope, the better it supports the outer strands and the higher the quality of the steel wire rope.

-

Materials: The material refers to the steel grade and strength. The higher the steel grade and strength, the better the quality of the steel wire rope.

-

Rope Characteristics: After cutting the rope, a slightly loose structure indicates good quality. Steel wire ropes with longer lay lengths are generally better in quality than those with shorter lay lengths.

-

Corrosion Resistance: 316 stainless steel wire rope has better corrosion resistance than 306 stainless steel wire rope, 306 stainless steel is more corrosion-resistant than hot-dip galvanized steel wire rope, and hot-dip galvanized steel wire rope is better in quality than electro-galvanized steel wire rope. Nylon-coated steel wire rope is superior in quality to PE-coated steel wire rope, PE-coated steel wire rope is better than PVC-coated steel wire rope, and coated wire ropes are more corrosion-resistant than galvanized steel wire ropes.

How to install and maintain wire rope?

Installation

-

Preparation: Make sure the work area is clean and safe, and prepare the necessary tools and equipment.

-

Check the wire rope: Before installation, check the wire rope for any damage or wear and ensure it is intact.

-

Correct winding: When winding the wire rope, avoid twisting and external damage. Use a dedicated winding table or wheel for winding.

-

Installation process: When installing the wire rope, ensure that it does not bend excessively or collide with the baffle when passing through the guide wheel and pulley to prevent damage.

-

Fixing and connection: Use appropriate connectors and tools to ensure that the wire rope is firmly fixed to avoid loosening or falling off.

Maintain

-

Regular Inspections: Conduct regular inspections of the overall condition of the steel wire rope, especially at seams, connection points, and high-stress areas, to identify any potential issues.

-

Rust and Dirt Removal: When the steel wire rope has rust and grime, use a wire brush to remove it and then apply oil.

-

Lubrication: Apply oil to the steel wire rope every 4 months. It is best to use hot oil (around 50°C) to soak through the rope core and then wipe off any excess grease.

-

Storage: After coiling the steel wire rope, store it in a clean, dry place, ensuring it is not stacked to prevent kinks.

-

Securing Rope Ends: Use steel wire to tightly bind the ends of the steel wire rope, or weld them with a low melting point alloy. Alternatively, use iron hoops to tighten, preventing the rope ends from unraveling.

-

Load Indicators: If oil droplets are squeezed out from the surface of the steel wire rope during use, it indicates that the rope is bearing a substantial load. In such cases, stop increasing the load and inspect the rope; replace it if necessary.

-

Tensile Capacity: The carrying capacity of the traction steel wire rope should be 5 to 8 times the total traction force.

-

Record Keeping: Maintain usage records of the steel wire rope, including installation dates, inspection dates, and maintenance logs, to track its usage history and condition.

-

Replacement and Disposal: Replace or dispose of the steel wire rope promptly if it shows obvious damage, wear, or decreased strength to ensure safety.

Steel Wire Rope Product In Meigesi Fastener

Meigesi Fastener has two types of DIN3055 standard steel wire ropes, one with PVC coating and one without PVC coating.

|

Specification |

|

2MM |

8MM |

|

3MM |

10MM |

|

4MM |

12MM |

|

5MM |

13MM |

|

6MM |

16MM |

At the same time, we also match the suitable wire rope clamp DIN741.

Market prospects of wire rope

At present, under the premise that there is no substitute for wire rope products, the demand for wire rope in various industries is gradually expanding. Benefiting from the growth of demand in the fields of construction, industry and agriculture, the market for wire rope is expanding. With the continuous advancement of global infrastructure construction, the demand for the application of wire rope in various engineering projects is also increasing. For such an important wire rope, it is very important to choose a good supplier. Meiges's wire rope is world-renowned. While ensuring quality, it is also at a preferential price and has good after-sales service. It is your best choice. Please feel free to contact us for relevant information.